Use this easy tool to help you determine the right PTO components for your set up - including the T14 Transmission PTO, S13 Rear Engine PTO, Bending Moment, Pump Flow and PTO Speed. You can complete each section of the calculator individually, and all calculations are based on the International S13 engine model.

To get started, please select your preferred measurement system.

Close

Transmission PTO Details

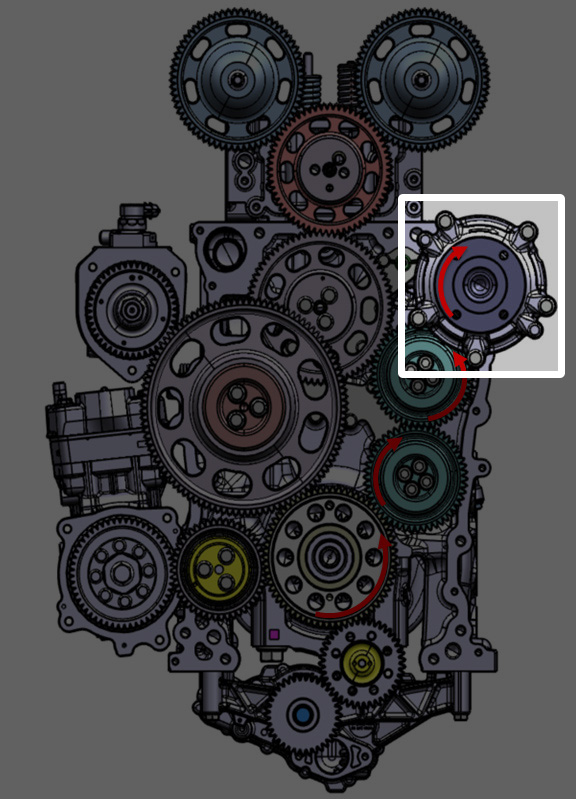

Transmission PTO rotation

Transmission PTO turns on a counter-clockwise rotation. See diagram for details.

Single vs. dual transmission PTO

If spec’d with a single transmission PTO, the PTO will be located on the bottom position.

RPM ranges

The ideal range for Pump/PTO Speed and Engine Speed is between 900-1200 rpm. Limit time spent above 1200 rpm.

Transmission PTO calculations

The following formulas are used when calculating values.

- PTO gear ratio = Pump/PTO speed ÷ Engine speed

- Pump/PTO speed = Engine speed x PTO gear ratio

- Engine speed = Pump/PTO speed ÷ PTO gear ratio

Reset Inputs

T14 Transmission PTO

Calculate one of the unknown variables below to determine the best PTO to use on the T14 transmission.

More Transmission PTO Details

1. Select Calculation

Which would you like to calculate?

Will a single or dual PTO be used?

2. Inputs

Pump/PTO Speed (RPM)

Engine Speed (RPM)

Engine Speed must be between 600-2300 RPM

PTO Gear Ratio

Engine Speed (RPM)

Engine Speed must be between 600-2300 RPM

PTO Gear Ratio

Pump/PTO Speed (RPM)

3. Results

PTO Gear Ratio

Pump/PTO Speed - Low Split

rpm

Pump/PTO Speed - High Split

rpm

The ideal rpm range is between 900-1200 rpm. Limit time spent above 1200 rpm.

Engine Speed - Low Split

rpm

Engine Speed - High Split

rpm

The ideal rpm range is between 900-1200 RPM. Limit time spent above 1200 RPM.

Close

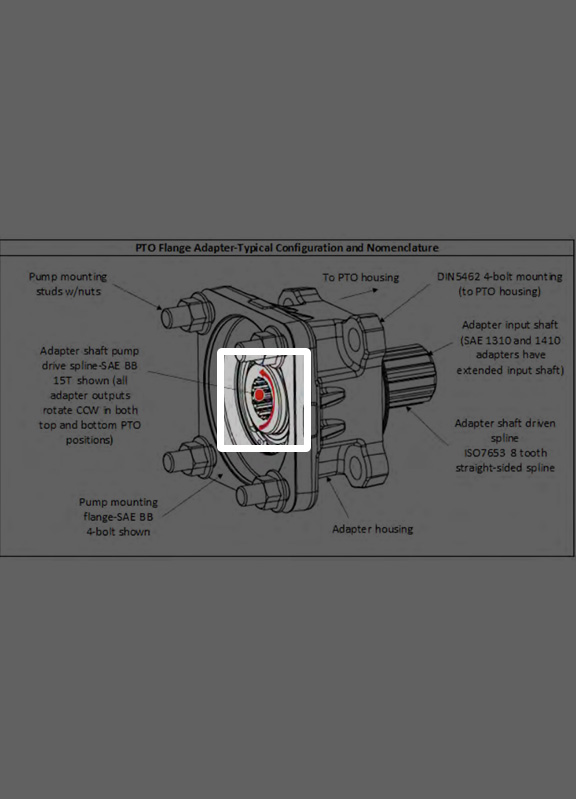

REPTO Details

REPTO Rotation

REPTO turns on a clockwise rotation. See diagram for details. The T14 PTO rotates counterclockwise,

while the REPTO rotates clockwise.

RPM Ranges

The ideal range for Pump/PTO Speed and Engine Speed is between 900-1200 rpm. Limit time spent above 1200 rpm.

Transmission PTO calculations

The following formulas are used when calculating values.

- Pump/PTO speed = Engine speed x PTO gear ratio

- Engine speed = Pump/PTO speed ÷ PTO gear ratio

Rear Engine PTO Gear Ratio is fixed at 1.2:1

Learn more about the upcoming DIN 5462 4-Bolt REPTO

Please reference the sales information letter to learn about the standardized DIN 5462 4-Bolt REPTO flange.

Reset Inputs

S13 Rear Engine PTO (REPTO)

Calculate one of the unknown variables below to determine the best REPTO to use on the S13 engine.

More REPTO Details

1. Select Calculation

Which would you like to calculate?

2. Inputs

PTO Gear Ratio

1.2:1

Engine Speed (RPM)

Engine Speed must be between 600-2300 RPM

PTO Gear Ratio

1.2:1

Pump/PTO Speed (RPM)

3. Results

PTO Gear Ratio

Pump/PTO Speed

rpm

The ideal rpm range is between 900-1200 rpm. Limit time spent above 1200 rpm.

Engine Speed

rpm

The ideal rpm range is between 900-1200 RPM. Limit time spent above 1200 RPM.

Close

Bending Moment Details

Bending moment application

The bending moment calculation only applies to transmission pumps.

Bending moment calculations

The following formulas are used when calculating values. These formulas represent calculations in metric units.

Total pump system weight

=

Weight of adapter + Weight of pump

Adapter bending moment

- Length = Weight of adapter x 9.81 x (Length of adapter ÷ 2)

- Center of Gravity (CG) = Weight of adapter x 9.81 x CG Distance adapter

Pump bending moment

- Direct Mount Length = Weight of pump x 9.81 x (Length of pump ÷ 2)

- Direct Mount CG = Weight of pump x 9.81 x CG Distance pump

- Adapter Length = Weight of pump x 9.81 x (CG Distance pump + Length of adapter)

- Adapter CG = Weight of pump x 9.81 x (CG Distance pump + Length of )

System bending moment = Adapter bending moment + Pump bending

moment

Read more on bending moment calculations

Reference pages 209-240 of the CT471 Body Builder Book for full explanations on bending moment calculations (note: bending moment calculation is consistent across truck models).

Reset Inputs

Bending Moment

Identify the ideal pump weight for the PTO to avoid reaching a critical bending moment.

More Bending Moment Details

1. Select Calculation

Will an adapter be used to mount the PTO pump?

Calculate bending moment using...

Calculate bending moment using...

2. Inputs

Adapter Type

Weight of Pump

lbs.

Switch to kgs.

Length of Pump

in.

Switch to meters

Weight of Pump

lbs.

Switch to kgs.

Length of Pump

in.

Switch to meters

Adapter Type

Weight of Pump

lbs.

Switch to kgs.

Center of Gravity Distance - Pump

in.

Switch to meters

Weight of Pump

lbs.

Switch to kgs.

Center of Gravity Distance - Pump

in.

Switch to meters

3. Results

Close

Pump Flow and PTO Speed Details

Hi/Lo PTO Switch

The Hi/Lo PTO switch is a Diamond Logic feature. See your dealership if your truck is not

equipped with this feature. Reference the diagram for an example of the switch.

Transmission PTO calculations

The following formulas are used when calculating values.

- Pump flow = (Displacement x Pump speed) ÷ 1000

- Pump/PTO speed = Engine speed x PTO gear ratio

Note: Hose diameter also impacts flow rate

Reset Inputs

Pump Flow and PTO Speed

Calculate the amount of hydraulic fluid that will pump through the lines to determine the optimal type

of pump to use.

More Pump Flow and PTO Speed Details

1. Select Calculation

Which would you like to calculate?

2. Inputs

Displacement

cu.in./rev

Switch to cc./rev

Pump Speed (RPM)

PTO Gear Ratio

Engine Speed (RPM)

Engine Speed must be between 600-2300 RPM

3. Results

Pump Flow

Pump Speed - Low

rpm

PumP Speed - High

rpm

Print Results

Print a PDF that includes a summary of any of the above sections that you’ve completed.